Getting your glass balustrade specification right the first time can save you thousands in mistakes and ensure your project meets all safety regulations. Whether you're a tradie working on a new build or a homeowner planning a renovation, understanding when to use 12mm, 15mm, or laminated glass: and when handrails are mandatory: is crucial for both compliance and long-term performance.

The choice isn't just about thickness. Australian Building Codes, wind loads, fall heights, and specific site conditions all play a role in determining the right glass specification for your balustrade project.

Understanding Glass Types for Balustrades

Toughened Glass: The Australian Standard

Toughened glass is the backbone of most balustrade installations across Australia. This heat-treated glass is approximately five times stronger than standard float glass, making it ideal for structural applications. When it does break, it crumbles into small, relatively harmless granules rather than dangerous shards.

The key thing to remember? Once toughened glass breaks, it's gone: there's no protective barrier left behind.

Laminated Glass: Safety First

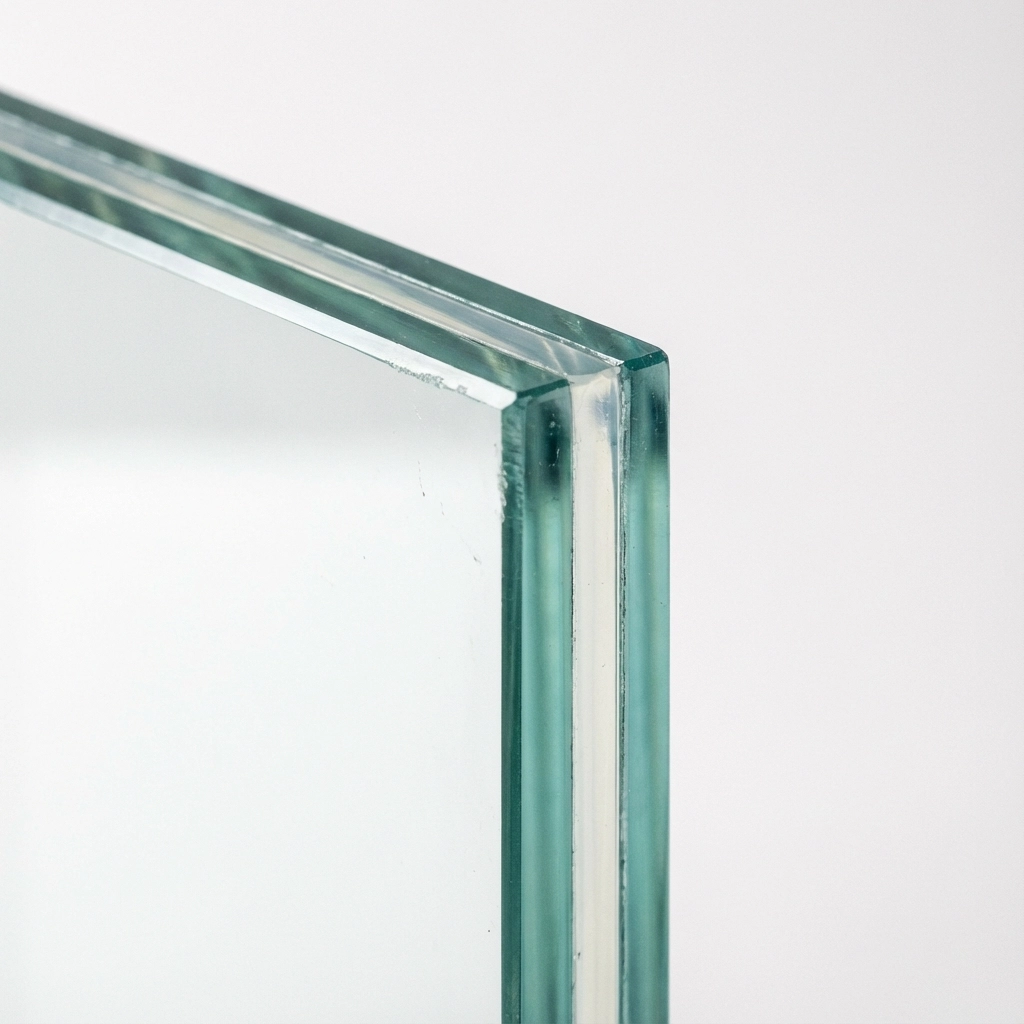

Laminated glass consists of two or more glass sheets bonded together with a tough plastic interlayer (usually PVB). The real advantage here is that when laminated glass breaks, the interlayer holds everything together, maintaining a protective barrier even after impact.

This makes laminated glass particularly valuable in high-risk areas or where maintaining a continuous barrier after breakage is critical for safety.

Toughened Laminated: Best of Both Worlds

Premium installations often use toughened laminated glass: combining the strength benefits of toughening with the safety advantages of laminated construction. This hybrid approach delivers maximum performance but comes at a higher cost.

When to Use 12mm Toughened Glass

Residential Applications

For most residential balconies, decks, and internal staircases, 12mm toughened glass hits the sweet spot between performance and cost. It's perfectly adequate for:

- Ground-level residential balconies

- Internal staircases and mezzanines

- Small to medium-sized outdoor decks

- Applications with spans under 1.5 meters between supports

Load Requirements

Standard residential loads typically require resistance to 0.74 kN/m horizontal line loads and 0.5 kN/m² infill loads. 12mm toughened glass handles these requirements comfortably while keeping costs reasonable.

Visual Appeal

The 12mm thickness provides excellent clarity and a clean, modern appearance without the visual bulk of thicker options. It's particularly popular in contemporary homes where maintaining sight lines is important.

At Glass House AU, our spigots for 12mm glass are engineered specifically for residential applications, providing secure, code-compliant mounting with minimal visual impact.

When to Use 15mm Toughened Glass

Higher Load Applications

Step up to 15mm toughened glass when you're dealing with:

- Elevated balconies (first floor and above)

- Larger spans between supports (1.5m+)

- Commercial applications

- Areas with higher wind loads

- Pool fencing in exposed locations

Structural Considerations

The extra thickness provides significantly higher load-bearing capacity and reduced deflection under pressure. This is particularly important for elevated installations where wind loads increase substantially.

Commercial Requirements

Many commercial applications mandate thicker glass due to higher safety factors and increased public access. 15mm glass provides the extra margin of safety required for these environments.

When Laminated Glass is Essential

High-Risk Environments

Laminated glass becomes essential in several scenarios:

Marine and Pool Areas Salt spray and chlorine exposure can be tough on glass hardware over time. Laminated glass provides superior UV protection and maintains its barrier function even if the glass is damaged by impact or environmental factors.

Overhead Applications Any glass installation above head height: like mezzanine floors or elevated walkways: should use laminated glass to prevent injury from falling glass fragments.

Child Safety Zones Areas with high child activity benefit from laminated glass because the barrier remains intact even after breakage, preventing falls through the opening.

Fire-Rated Applications Some building codes require fire-rated glass in specific locations. Toughened laminated glass with appropriate interlayers can meet these requirements.

Our 17.52mm glass spigots are specifically designed for laminated glass applications, providing the structural support needed for these thicker, heavier panels.

Understanding Handrail Requirements

When Handrails Are Mandatory

Australian Building Codes require handrails in specific situations:

- Glass height under 1000mm from finished floor level

- Balustrades with openings larger than 125mm

- Stair balustrades (always require handrails)

- Some commercial applications regardless of glass height

Glass-Only Solutions

Where codes permit glass-only balustrades (typically 1200mm+ height for residential), you can achieve that clean, uninterrupted look. However, structural requirements become more demanding, often necessitating:

- Thicker glass (15mm minimum)

- More robust fixing systems

- Additional intermediate supports

Hybrid Approaches

Many projects use a combination approach: glass panels with minimal handrails that satisfy codes while maintaining aesthetic appeal.

Glass House AU Solutions for Every Application

Spigot Systems

Our range covers all common glass thicknesses:

- 12mm spigots: Perfect for residential applications with moderate loads

- 15mm spigots: Ideal for elevated installations and commercial projects

- 17.52mm spigots: Engineered for laminated glass systems requiring maximum strength

Each spigot system is designed and tested to Australian standards, ensuring code compliance and long-term reliability.

Channel Glazed Systems

For projects requiring continuous glass runs or specific aesthetic requirements, our channel glazed balustrade systems provide:

- Clean, continuous glass appearance

- Excellent structural performance

- Simplified installation process

- Compatibility with various glass thicknesses

Making Your Decision: A Practical Guide

Step 1: Assess Your Environment

- Ground level or elevated?

- Marine/pool exposure?

- High wind area?

- Commercial or residential use?

Step 2: Check Building Requirements

- Local council requirements

- Australian Building Code compliance

- Structural engineer specifications

- Fire rating requirements (if applicable)

Step 3: Consider Long-Term Factors

- Maintenance accessibility

- Replacement costs

- Environmental durability

- Aesthetic longevity

Step 4: Budget Analysis

- Initial glass costs

- Installation complexity

- Long-term maintenance

- Potential replacement needs

Professional Installation Matters

Regardless of which glass specification you choose, professional installation is crucial. Incorrect installation can compromise both safety and performance, potentially voiding warranties and creating compliance issues.

Always work with certified installers who understand local building codes and have experience with your specific glass type and fixing system.

Your Next Steps

Ready to specify the right glass for your balustrade project? Start by getting a structural assessment of your specific application: this will determine the minimum requirements you need to meet.

From there, consider your long-term goals, environmental factors, and budget to make the final choice between 12mm, 15mm, or laminated glass options.

Visit our glass balustrade hardware collection to explore our complete range of spigots and channel systems, or contact our technical team for project-specific guidance. With the right glass specification and quality hardware, your balustrade project will provide years of reliable, attractive service while meeting all safety requirements.